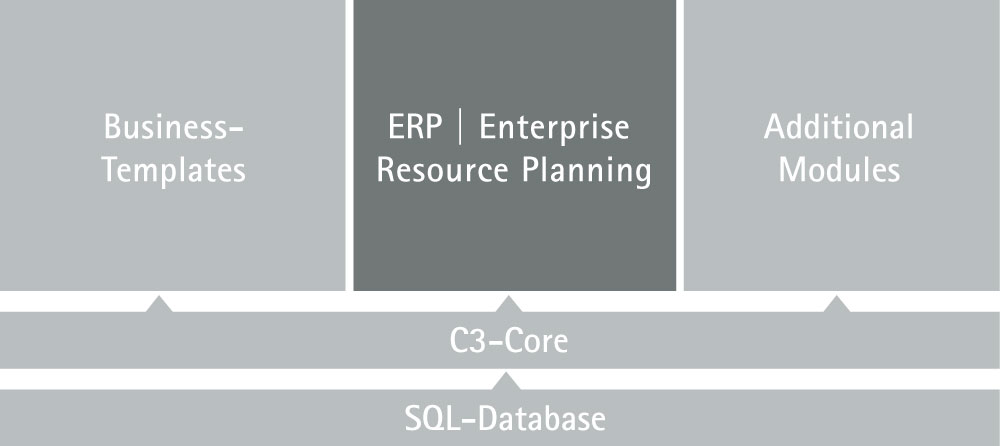

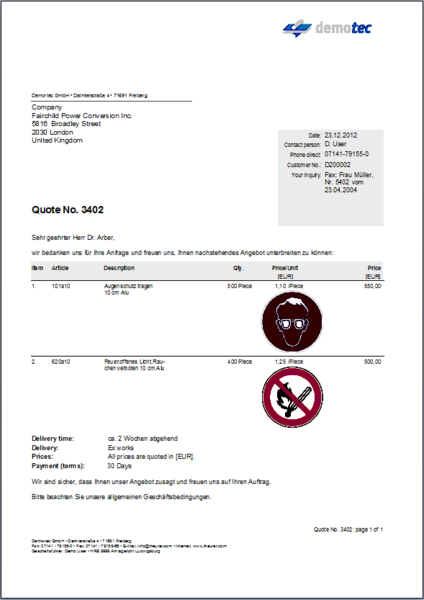

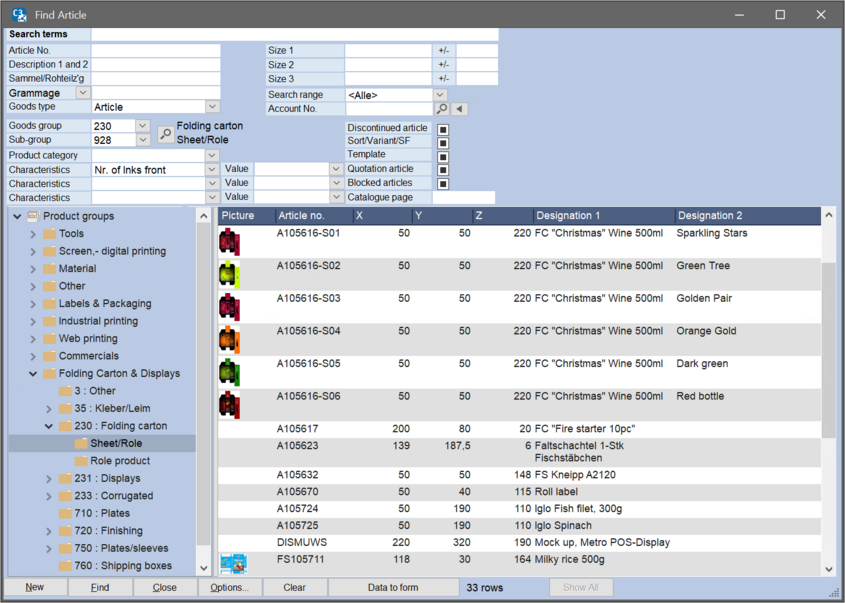

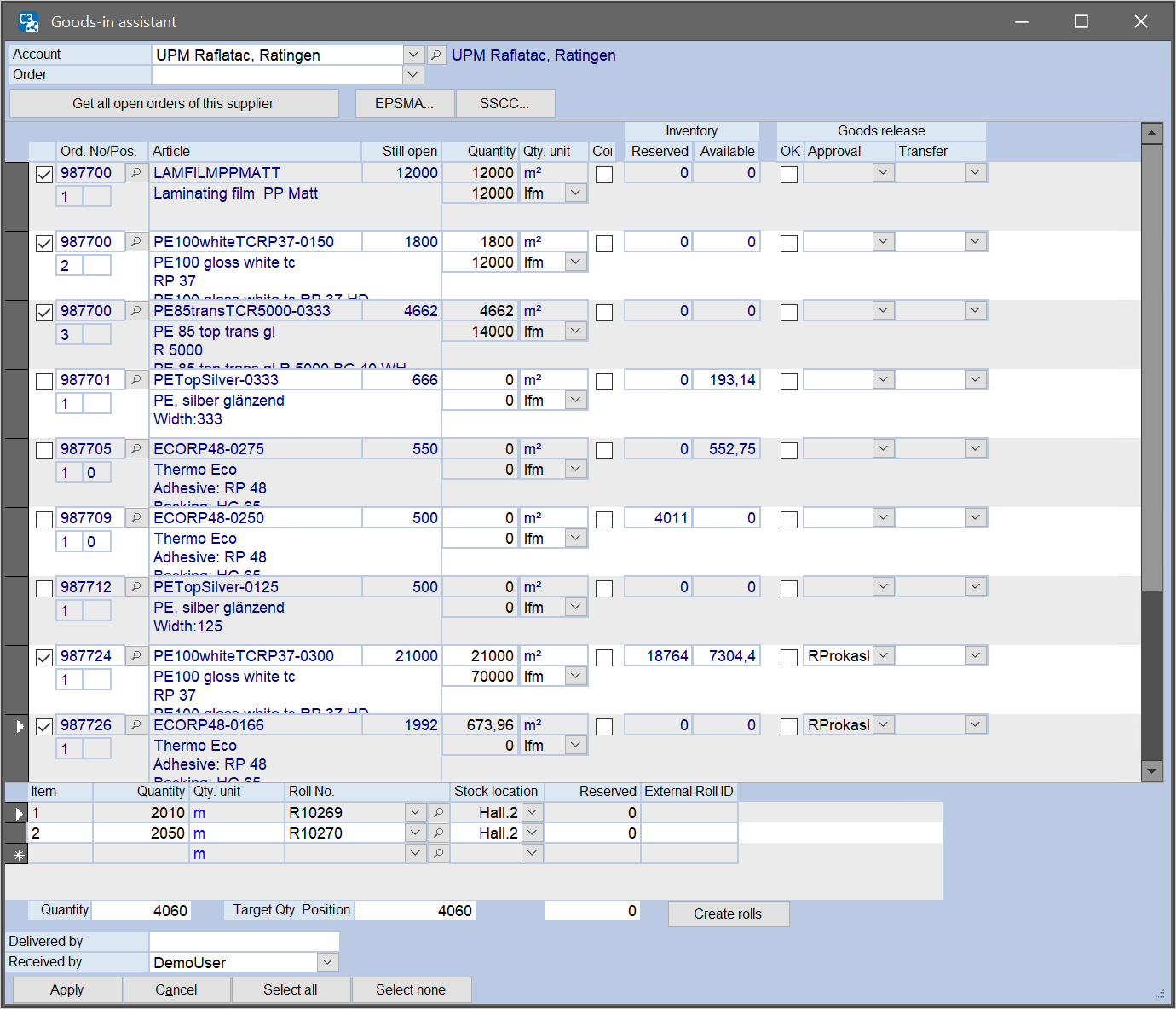

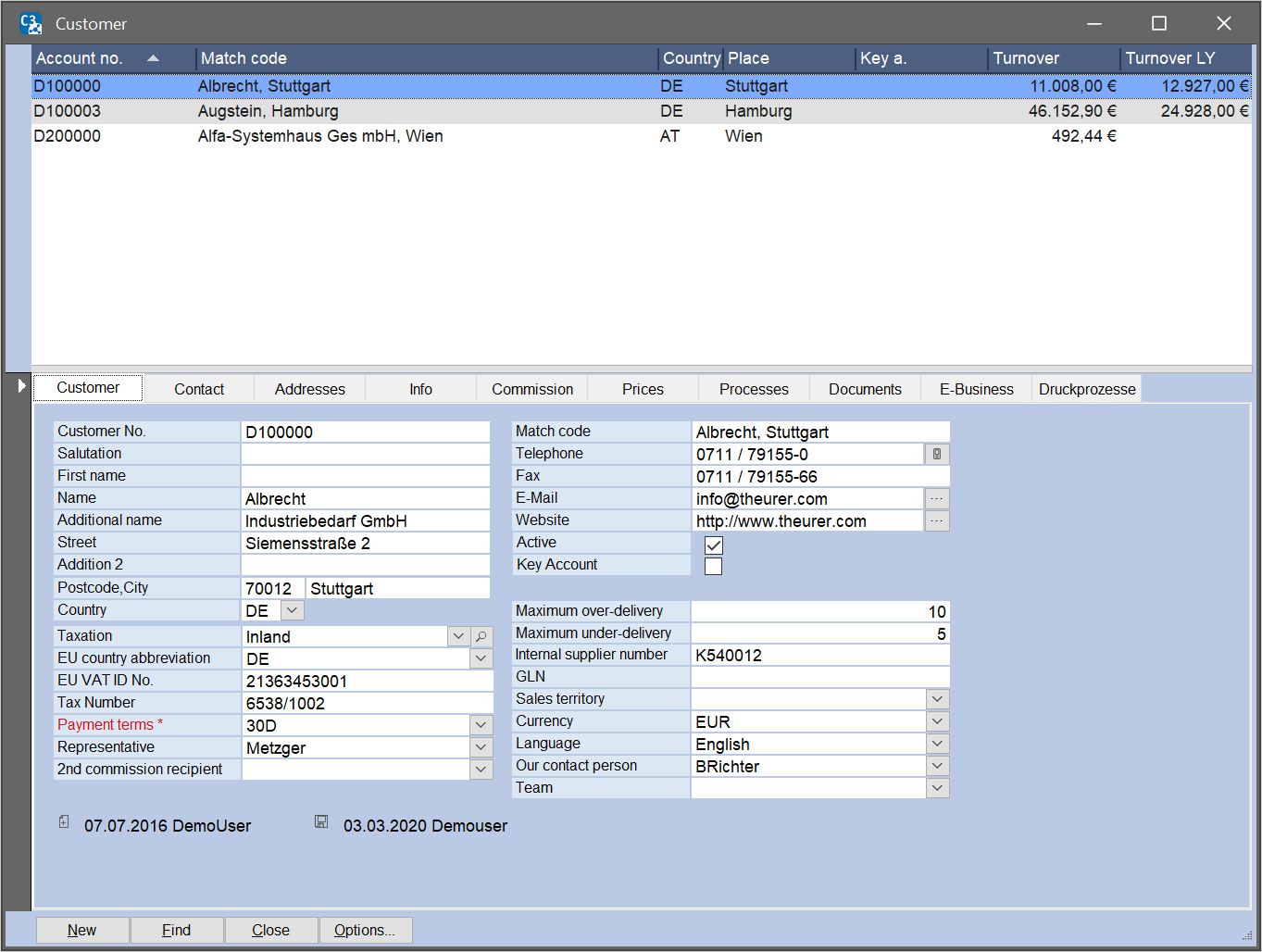

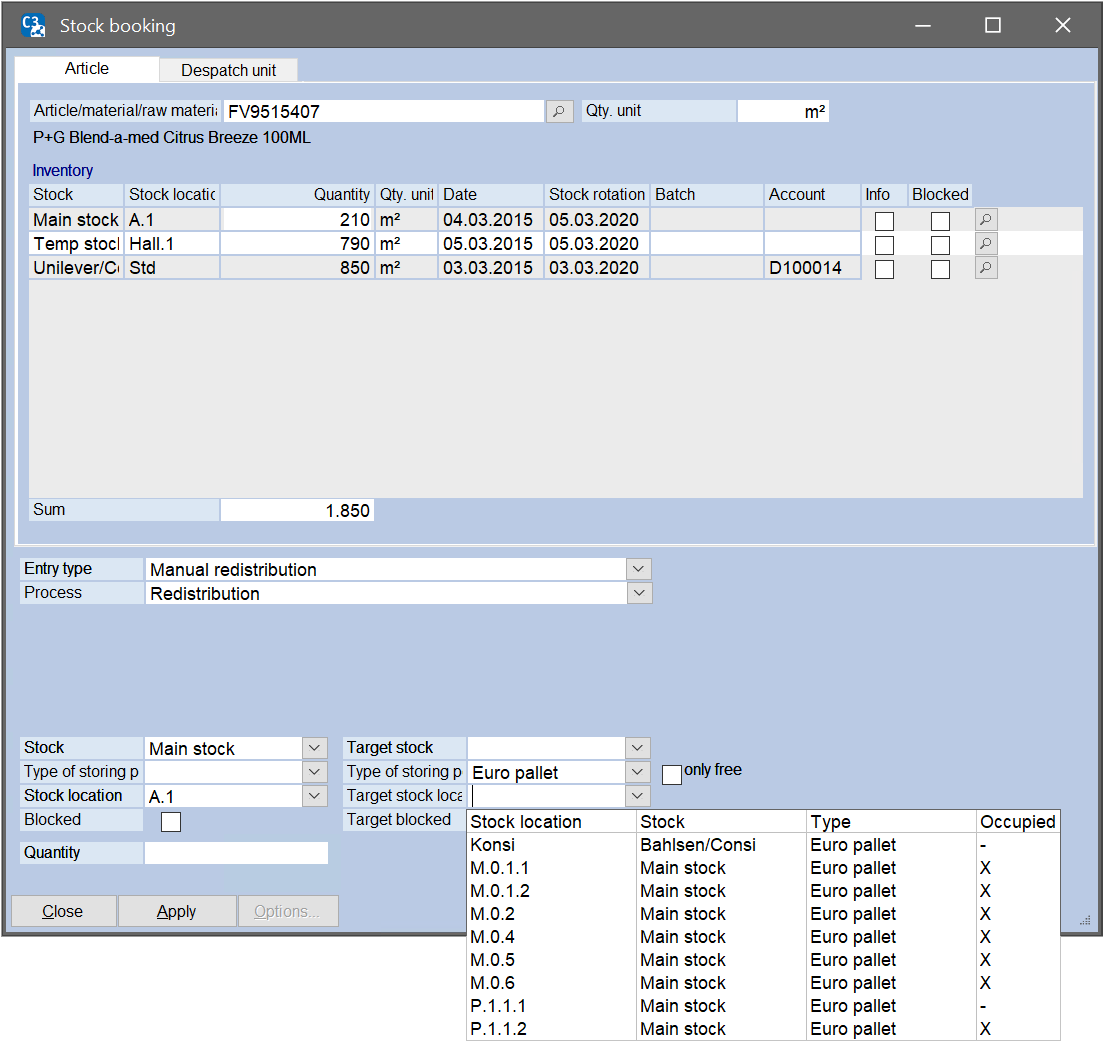

Practice-oriented business processes on a commercial basis are among the must-have elements of business. Whether you produce products yourself in-house to order or otherwise trade in them, you need a fully developed warehouse management system at all times. The ERP | Warehouse management system module includes all business processes on a commercial basis in the fields of sales, purchasing, warehousing and logistics. All sales processes, from the offer phase up to shipping, intermesh seamlessly in tacks and are automatically linked with the relevant purchasing processes. Routine business tasks, such as compiling an inventory or generating accompanying documents, e.g. proforma invoices, can be handled swiftly and easily with tacks.

Your key advantages

- You are best placed to handle future requirements thanks to practice-oriented ERP-standard functionality with a large function list

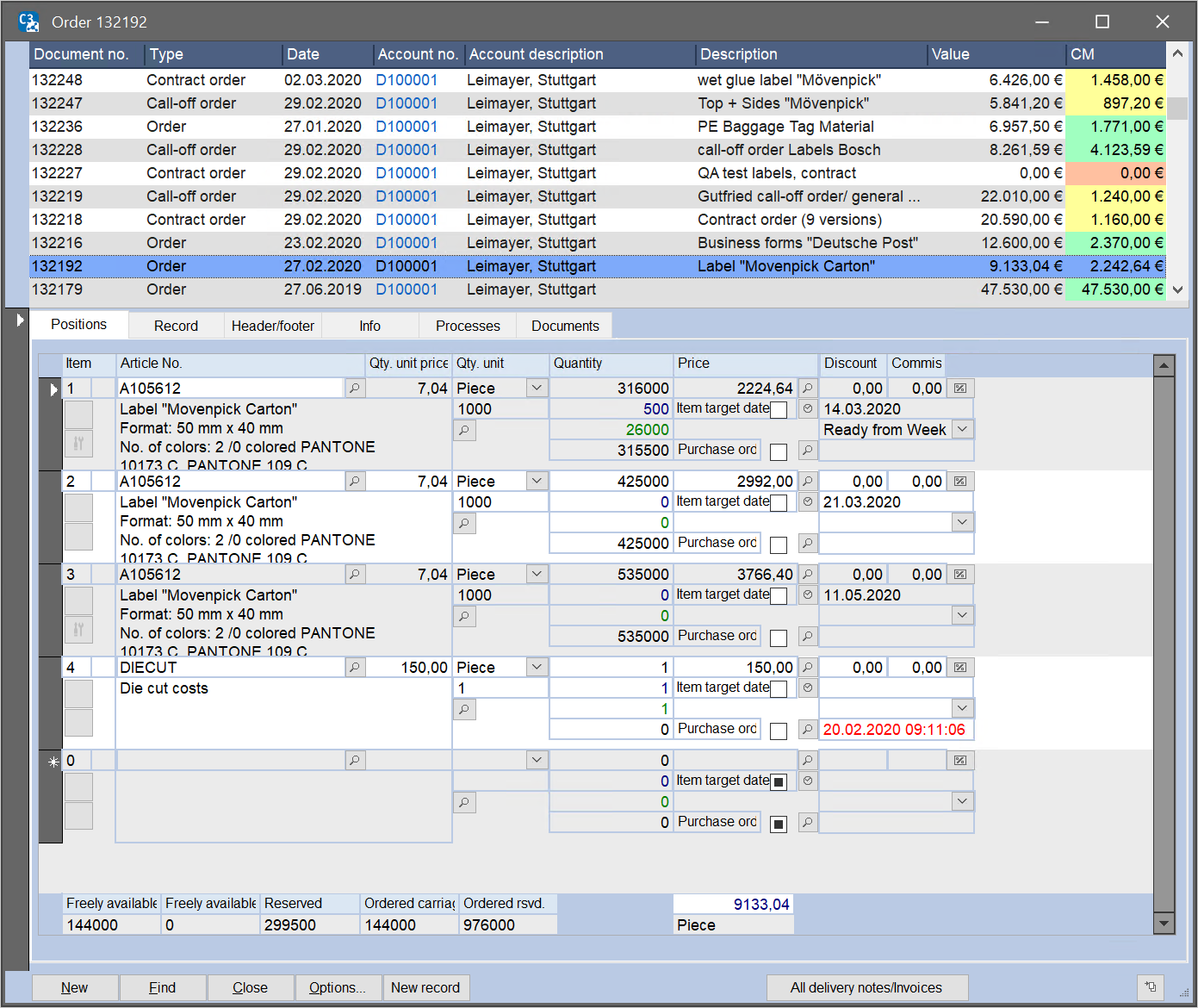

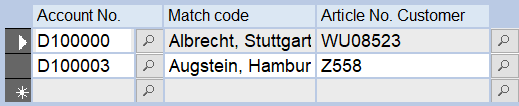

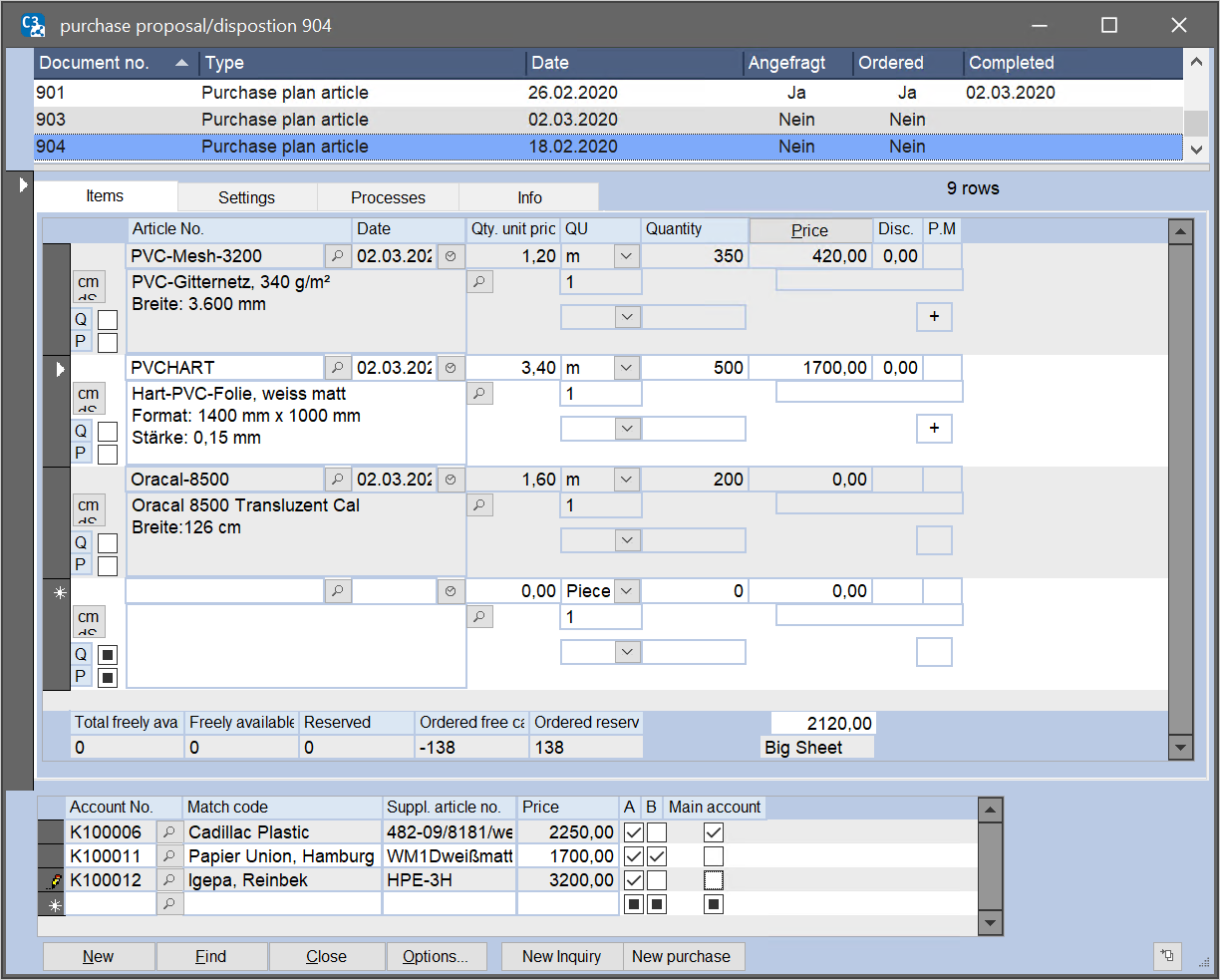

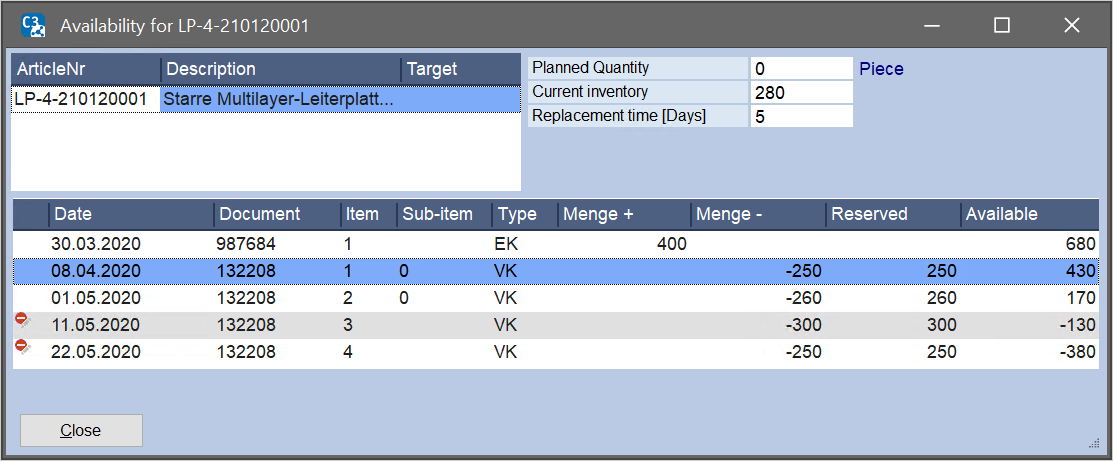

- Even complex structures such as contract orders with call-offs and partial deliveries or advance payment are both transparent and traceable

- Support your purchasing division by focusing on the key areas, and allowing C items to be arranged automatically via minimum or reorder levels

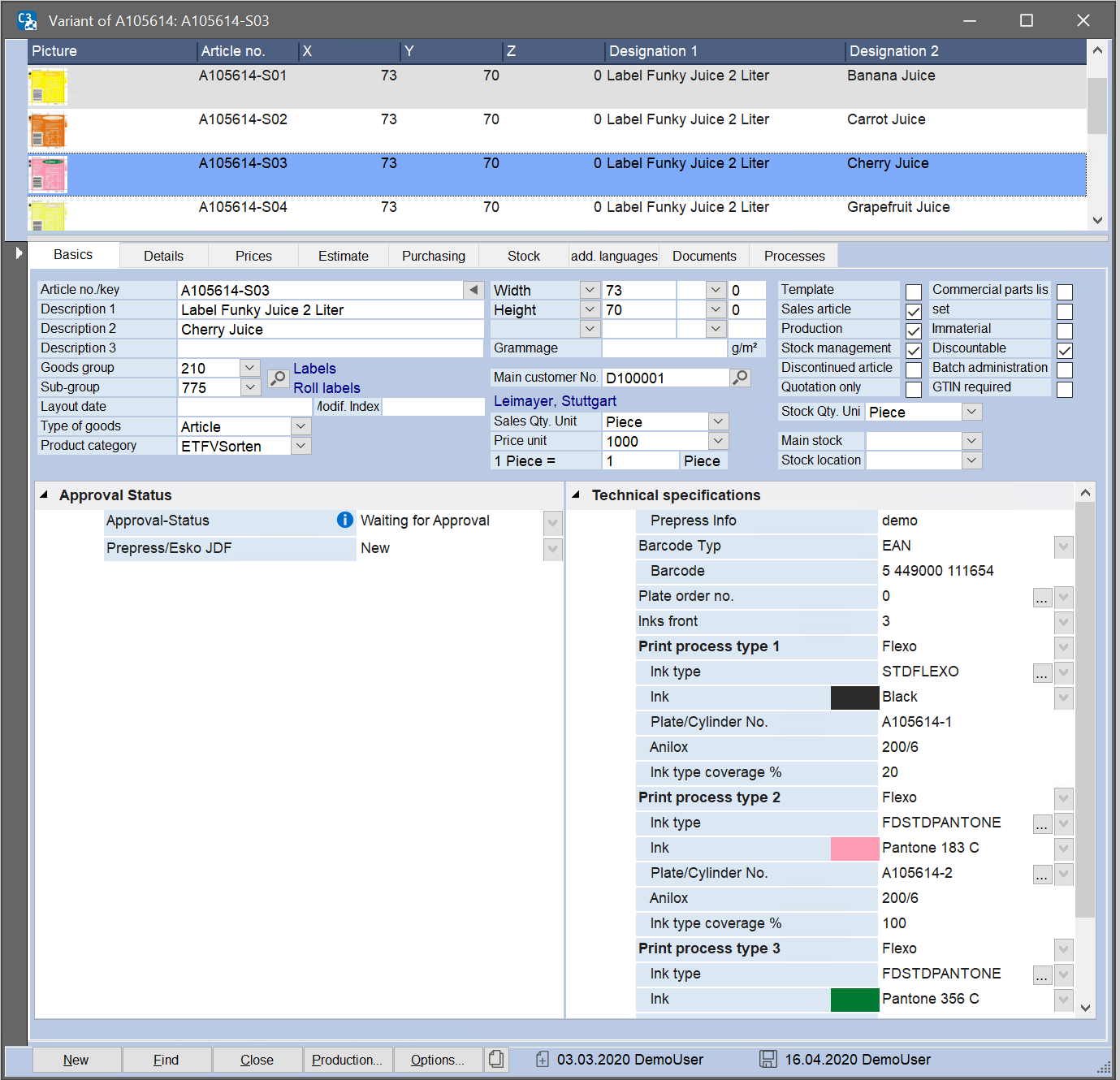

- Dates and stocks of finished or semi-finished goods are checked and managed