The graphical scheduling board of tacks supports you optimally in your manufacturing planning and control. In connection with the automatic capacity planning and automatic scheduling, a preliminary plan can be done by tacks automatically. In the process of the detailed planning you determine the optimal sequence for each resource. New or existing orders can comfortably be moved by Drag-and Drop until the desired place is found. Different filters and views help you to find an optimal manufacturing sequence for each resource that meets your company specific restrictions. The Graphical scheduling board is a powerful tool to reduce Make Ready times and the pass-through. This results in detailed day or week plans as print outs or directly on each users PC. The current progress status is clearly visible. Any manufacturing delays or machine breakdowns can be immediately noticed from the office

All manufacturing relevant data or manufacturing variants of an article are centrally administered in working plans. A working plan consists of individual work steps and a bill of materials. Target time and material consumption details build the baseline of the estimate and a material requirements analysis or a calculation of the earliest possible delivery date.

Overview of current production orders

The production order includes all information and data which are relevant for in-time manufacturing and quality assurance. There all target values are recorded such as which material shall be taken in which quantity from which inventory location. The manufacturing is supervised comprehensively in progress. Deadlines for each department can be entered and controlled. The actual data concerning the status and progress of a certain order comes from the data collection at the shop floor. The user therefore is always up to date on the status and progress of a certain order. Meeting delivery deadlines or giving useful information about order progress is made simple.

A special aspect is the assurance of the product quality. With detailed production orders combined with the shop floor control system, quality problems can be determined and solved in time. Details for each work step in a production order inform your employees of particular technical features and requirements to make sure that problems that have already occurred will not happen again.

The tacks capacity planning supports the coordination deadlines, production orders and shift plans with each other. tacks automatically calculated earliest start dates and latest completion dates for every involved department or for individual work steps. As a result a detailed capacity forecast is possible and adjustable for delivery times or shift plans in time.

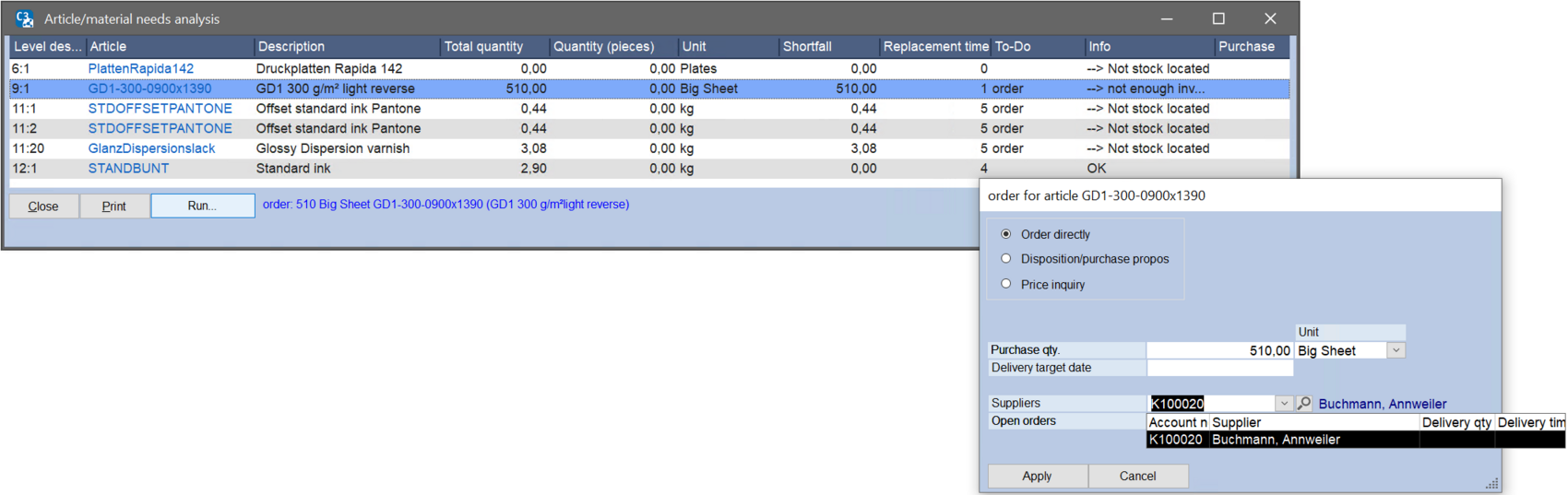

tacks supports you optimally in the material requirement planning. For an article or a production order, each material or article consumption is calculated. Consumption of bills of material at several levels can be allocated by article. Depending on the current inventory and the reordering time of articles or materials, purchase orders can be generated automatically or manually.